Metal lathes are machines designed for machining parts with rotational surfaces, such as cylinders, cones, spheres, and for cutting internal and external threads. They are used in both manufacturing and repair, ensuring precision and reliability.

Using a lathe, it is possible to produce various types of tools and machine parts. Knowing the main types of metal lathes is essential for selecting the right equipment for specific tasks.

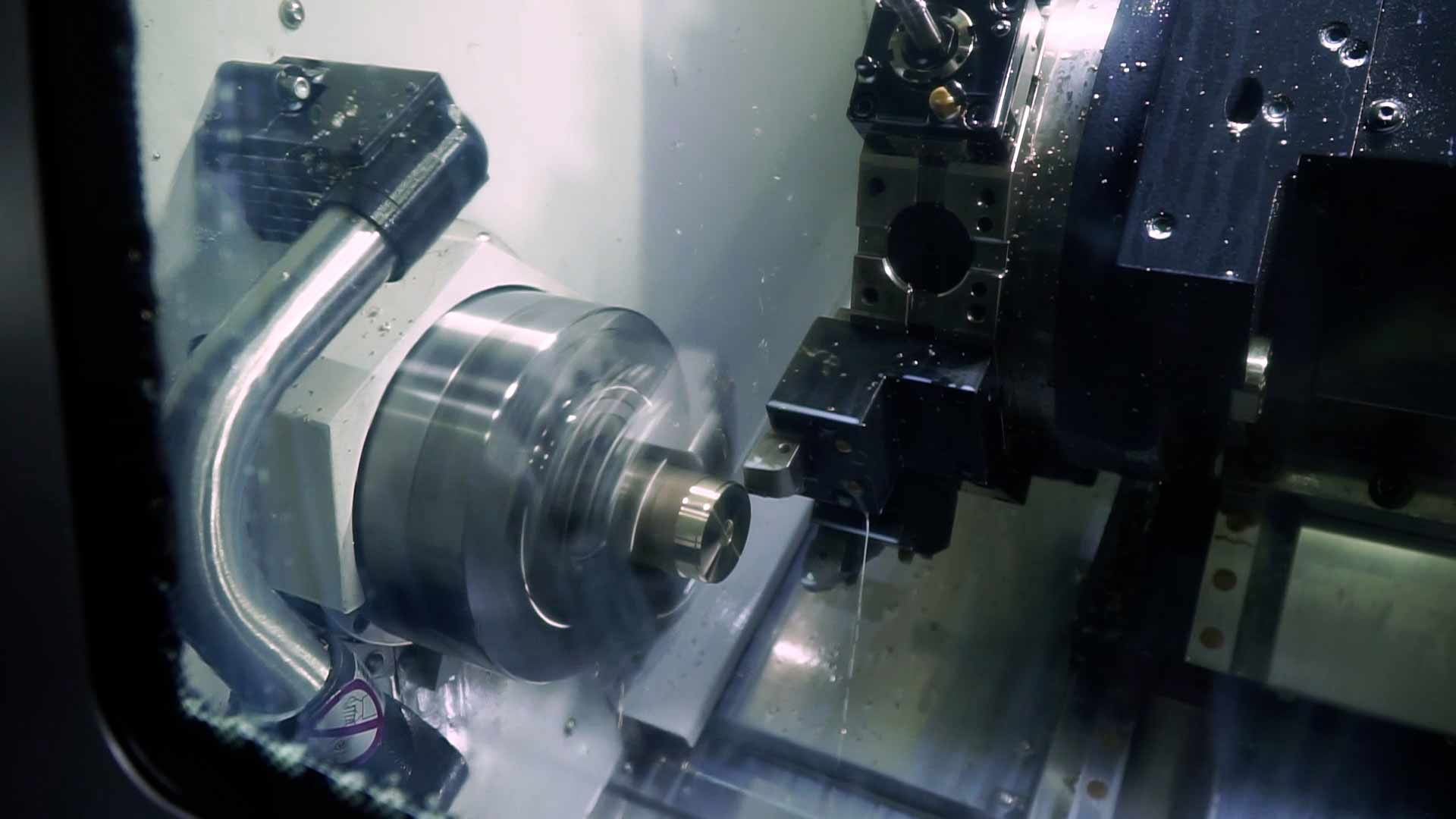

CNC Lathes

CNC stands for Computer Numerical Control. The main advantage of CNC lathes is their automation, which minimizes operator involvement—a critical feature in serial and mass production. CNC machining is fast, precise, and capable of creating highly complex shapes. These lathes are widely used in the manufacturing, construction, automotive, and watchmaking industries.

Conventional Lathes

Conventional lathes are commonly used for single-piece or small-batch production and for pre-processing tasks before machining on CNC lathes. These lathes allow for accurate roughing and finishing operations, such as threading and machining parts made of steel, non-ferrous metals, or cast iron. Due to their versatility, they are found in repair shops, tool rooms, production facilities, and service companies.

Longitudinal Lathes

Longitudinal lathes require minimal intervention during operation thanks to their high level of automation. Their precise control makes them ideal for serial production of long, small, and complex parts. These lathes are highly valued in the medical and electronics industries for their accuracy, speed, and compactness.

Center Lathes

Center lathes are versatile and efficient machines with a compact design and broad industrial applications. They are used for machining rotational surfaces, such as threads, balls, rollers, and cones. These lathes are indispensable in optical, metallurgical, automotive, and watchmaking industries.

Vertical Lathes

Vertical lathes are used for machining parts with large diameters and low heights. Their design ensures high stability and allows for the processing of large-sized workpieces. Depending on the configuration, the following types of vertical turret lathes are distinguished:

- Single-column lathes with a horizontal worktable up to 1100 mm in diameter;

- Single-column lathes with an extendable table;

- Lathes with an adjustable support;

- Double-column lathes with a horizontal worktable up to 3500 mm in diameter.

These lathes are primarily used in metallurgy, automotive, and weapons manufacturing.

Heavy-Duty Lathes

As the name suggests, heavy-duty lathes are used for machining and boring heavy and oversized workpieces. Equipped with powerful motors and reinforced guides, they are capable of handling high-strength alloys.

These lathes are highly versatile. They can be used for threading, surface milling, rough or transverse turning, and many other operations. They are intended for medium- and large-scale production tasks in industries such as energy, aerospace, machine building, and automotive manufacturing.

Understanding the features and advantages of each type of metal lathe enables the selection of equipment that will best meet the needs of your production.