Injection Molding

Injection molding is an advanced technology for producing high-quality plastic parts that is widely used in various industries. Thanks to modern equipment and highly qualified specialists, the «Promservice» company ensures the manufacture of products that meet the highest quality standards.

We provide a full cycle of plastic product manufacturing: from part design, mold making to injection molding. In addition to plastic molding, we also own Metal Injection Molding technology.

Our specialists have extensive experience in the field of plastics injection molding and are able to produce parts of any complexity. We guarantee high product quality and compliance with the terms of delivery.

Advantages of Injection Molding

By choosing injection molding, you can always rely on the following advantages:

High Production Speed

The technology enables the rapid manufacturing of a large number of parts with minimal equipment downtime.

Cost-Effective Process

Thanks to precise raw material dosing, injection molding optimizes material consumption and reduces waste.

Automation of Work

The plastic injection molding process minimizes human factor influence, improving production accuracy and ensuring consistent product quality.

Precise Product Geometry

Each plastic part produced meets the specified parameters and can be replicated in the required quantity without quality loss.

Variety of Materials

Injection molding allows the use of a wide range of polymers, enabling the creation of products with different properties and characteristics.

Injection molding - manufacturing aspects

Injection molding requires a high level of professionalism and precision at all stages of production. This process includes preparing polymer raw materials, accurate dosing, melting and injecting them into a mold under high pressure. Modern equipment provides optimal conditions for polymer casting, ensuring the high quality of finished products.

One of the key aspects of die casting is quality control at every technological stage. As a reliable manufacturer, Promservice implements modern methods of product control and testing, which minimizes the risk of defects and ensures that products comply with the declared technical characteristics.

Materials and their features

We work with all types of engineering plastics, as well as materials for Metal Injection Molding

Polyolefins (polyethylene, polypropylene)

They are distinguished by high chemical resistance and flexibility, making them ideal for the production of packaging and containers.

Styrenic plastics (polystyrene, ABS plastics, SAN plastics)

They have high strength and rigidity and are often used in the production of household goods.

Polyamides

They are distinguished by exceptional strength and wear resistance, making them ideal for the manufacture and repair of technical parts.

Polycarbonates

They are highly impact resistant and are widely used in the automotive industry and the production of protective casings.

Polyurethanes

They have a wide range of rigidity and elasticity and are used for affordable flexible molds and shock-absorbing elements.

Fluoroplastics

They have high heat resistance and non-stick properties, making them ideal for high temperature applications.

Polyester-based plastics

They are distinguished by good resistance to chemicals and are used in medicine and electronics.

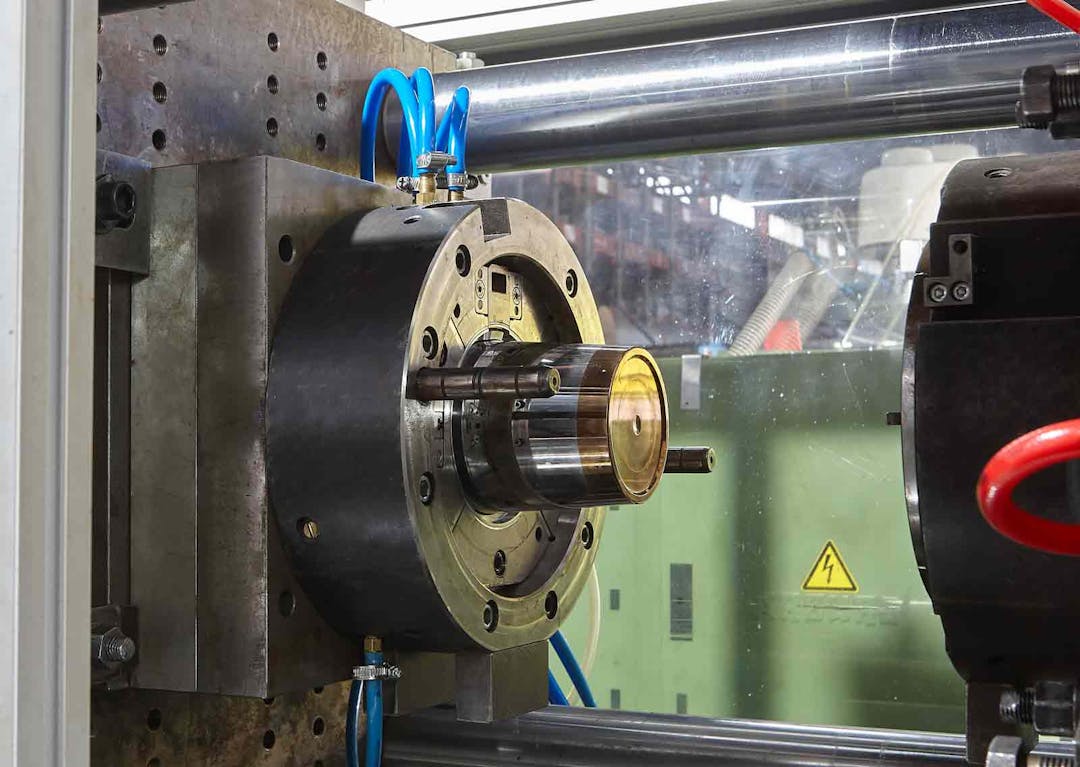

Injection molding equipment

We have a fleet of modern equipment consisting of 22 injection molding machines from 50 to 650 tons

Applications of Injection Molding

Injection molding is widely used in various industries due to the high precision, strength, and durability of the manufactured products. This method is applied in the following sectors:

Automotive Industry

Manufacturing parts for automobiles, such as panels, housings, and interior components.

Electronics

Production of casings for mobile phones, tablets, and other electronic devices.

Construction

Manufacturing of façade structures, fittings, and fasteners that are strong and durable.

Household Appliances

Creating components for refrigerators, washing machines, and other household devices.

Healthcare and Medicine

Production of medical instruments, packaging, and other healthcare-related items.

Mechanical Engineering

Manufacturing high-precision components for industrial mechanisms, enhancing equipment lifespan and productivity.

Advantages of injection molding at Promservice

Promservice offers injection molding services, guaranteeing a professional approach at every stage of production. Highly qualified specialists and modern equipment allow us to satisfy the most demanding customer requirements. At the same time, the cost of products remains inexpensive and accessible to everyone, and it can be obtained in a convenient way for the customer, both within Ukraine and around the world.

We work with all engineering plastics

Flexible program for the production of parts from single to large-scale

Free maintenance and storage of molds

Wide range of part sizes

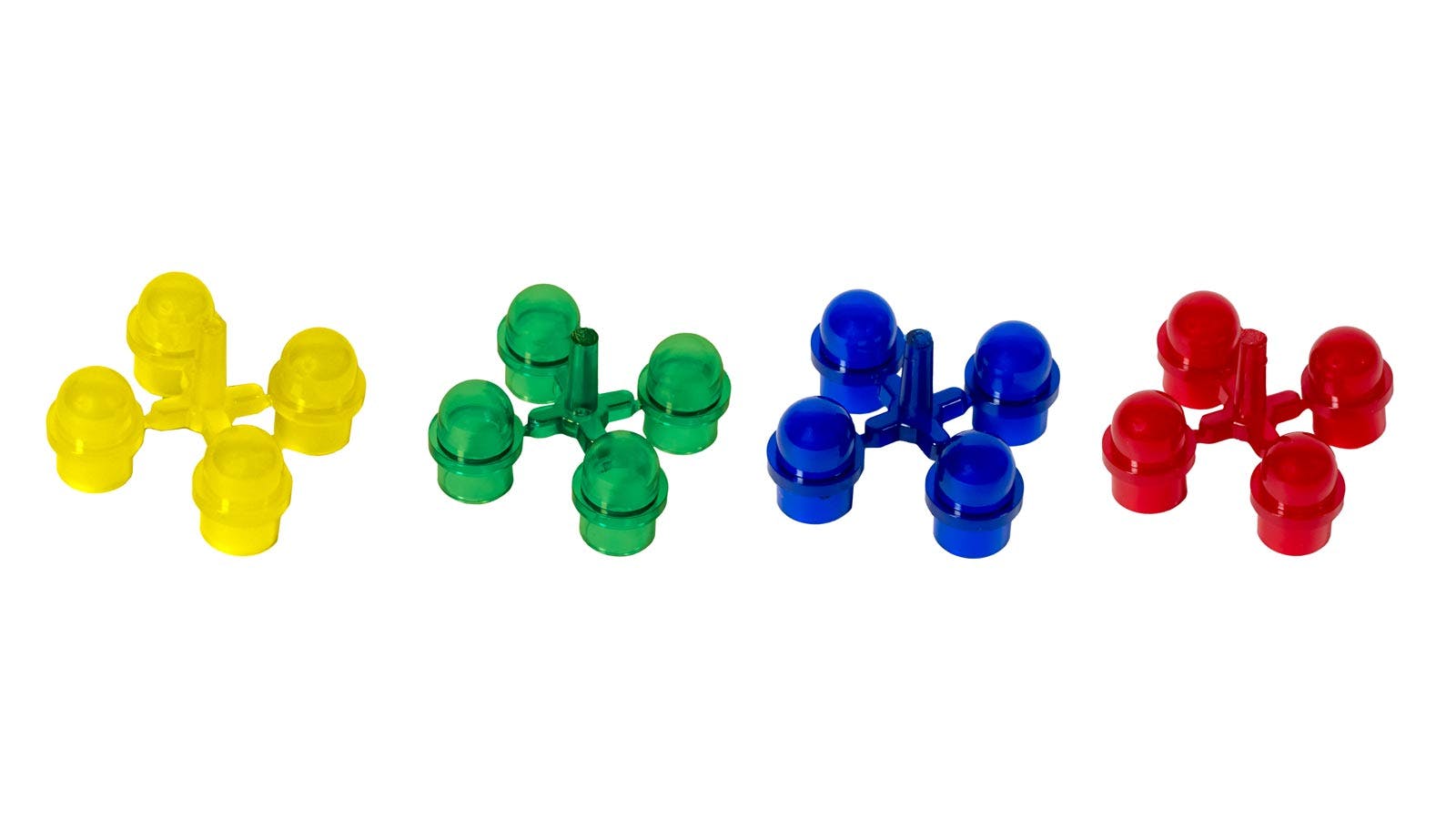

Portfolio

.jpg&w=3840&q=75)

-2.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

-2.jpg&w=3840&q=75)

-2.jpg&w=3840&q=75)

.jpg&w=3840&q=75)