Mold design

Mold design is an important stage in manufacturing, on which the foundation of the future project is laid. The project determines the quality and timing of the mold manufacturing, as well as the quality and timing of the finished products, so the mold design should be carried out by a qualified team of specialists who will take into account all the nuances and features of a particular project.

«Promservice» LLC provides mold design services for injection molding and direct pressing of plastics. Our design office has extensive experience in designing molds for a wide range of products, from simple parts to complex structures, specialists use modern CAD, CAM and CAE systems to create accurate and reliable projects.

Plastic mold design is one of the key activities of Promservice, a company specializing in the creation of high-quality molds for injection and direct compression molding of plastics. Thanks to their deep knowledge of technologies and the use of advanced software solutions, Promservice engineers develop molds that perfectly meet technical requirements and optimize customer production processes. We offer comprehensive services for the manufacture of molds, while guaranteeing their low cost with the possibility of prompt order fulfillment within Ukraine.

Mold design is a complex and responsible process that requires specialized knowledge and experience. As a reliable manufacturer, we have everything we need to develop models of any complexity, providing reliable and affordable products. Contacting Promservice for the design and manufacture of molds guarantees the receipt of high-quality parts that meet all modern standards.

Options for Mold Design

Molds for Injection Molding of Plastics

The design of molds for plastic injection molding involves creating a structure that allows the molten polymer to quickly and evenly fill the mold. The main requirements for such molds are: high geometric accuracy, optimal cooling parameters, and efficient gating system placement. This helps reduce the number of defects, ensuring that finished products require minimal post-processing.

Molds for Compression Molding

When designing molds for compression molding, the focus is on the uniform distribution of material under compression. The main requirements are: resistance to significant mechanical loads, high density and stability of finished parts, a design that considers the characteristics of the material.

Mold design stages

1. Obtaining and analyzing the technical specification

At this stage, the geometry of the product, its functional requirements and operating conditions are studied. The product design is also analyzed and requirements for the mold are determined taking into account the customer's equipment.

2. Development and approval of the operational sketch

At this stage, the product design is optimized, an operational sketch is developed, which is approved with the customer.

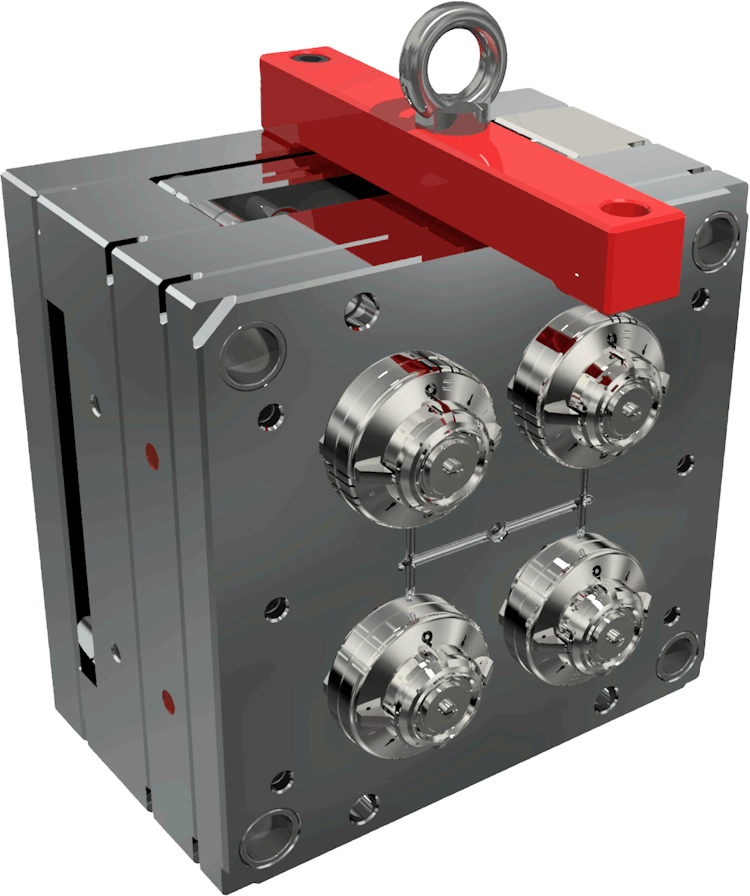

3. Development of the mold design and 3D model

At this stage, the mold design, its configuration and parameters are determined. The result of this stage is an assembly drawing and a 3D model of the mold.

4. Approval of the assembly drawing with the customer

The assembly drawing is approved with the customer.

5. Development of design documentation

At this stage, design documentation is developed, which is used for the manufacture of the mold. Detailing with drawings and 3D models, determination of purchased and standardized parts.

Our advantages

High qualification of specialists

Use of modern CAD, CAM and CAE systems

Experience in designing molds for a wide range of products

Individual approach to each customer

Mold Design - Main Stages

The first stage of mold design includes a detailed analysis of product requirements, determination of the type of mold and materials for its manufacture. At this stage, a product concept is developed that takes into account all aspects of production, from its volume to the performance characteristics of the finished product.

The second stage involves the creation of a detailed mold design using CAD/CAM systems. This allows you to determine the optimal design of the mold, calculate its strength and efficiency, and make the necessary adjustments before production.

Molds and Their Applications

Molds play a key role in the production of a wide range of plastic products. Among the main examples of their use are:

Packaging

Production of containers, bottles, lids necessary for the food industry and in everyday life.

Medical Products

Creation of medical equipment housings, containers for medicines.

Construction Industry

Manufacturing of various interior and exterior elements, such as ventilation grilles, sewer pipes.

Household Appliances

Creation of components for refrigerators, washing machines, vacuum cleaners.

Children's Toys

Production of toys of various shapes and sizes, safe for children.

Electronics

Development of cases for mobile phones, tablets, laptops.