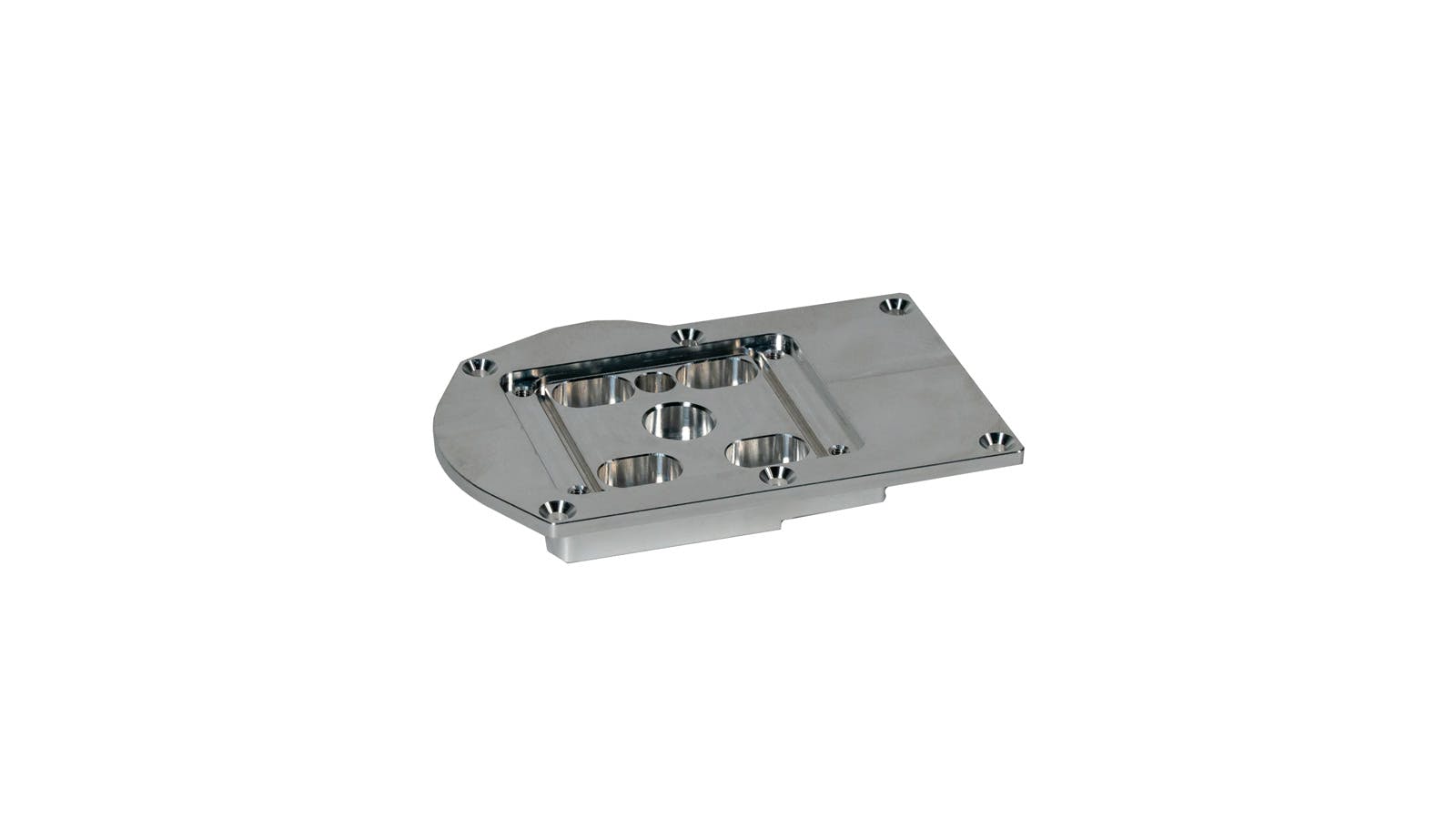

Metalworking and parts manufacturing

Metalworking and manufacturing of parts is a process that requires high precision, professionalism and modern equipment. The Promservice company stands out in the market due to its many years of experience and the use of advanced technologies in this field. Our team provides high quality metal processing and is always ready to produce products according to individual orders.

The company «Promservice» offers a wide range of metalworking services, as well as carries out a full cycle of work on the manufacture of parts according to the technical specification. We carry out work of any complexity (within the dimensions of our equipment), from simple lathe and milling operations to complex EDM and CNC work.

Our technological bureau has extensive experience in working with projects of varying complexity, and an extensive fleet of equipment allows us to perform large volumes of work efficiently.

Metalworking and Parts Manufacturing - Specifics of Implementation

Metalworking includes a number of procedures, each of which plays a key role in creating high-quality products. The process of manufacturing parts begins with careful design and selection of materials, ensuring the accuracy and durability of the final product. Modern production and qualified specialists allow us to bring to life the most complex projects, meeting the needs of even the most demanding customers.

Approaches to metalworking, repair and manufacture of parts in «Promservice» are based on the integration of traditional methods with innovative technologies. This allows us to achieve unsurpassed processing accuracy and optimize the cost of production processes, reducing the production time of products without sacrificing their quality.

Metalworking - Main Directions

Among the most relevant metalworking services are:

- CNC milling. Used for surface processing, creating cutouts and grooves of various configurations.

- CNC turning. It allows you to produce parts with high accuracy due to automated process control.

- Electro-erosion work. Used to create complex-shaped parts, as well as to process hard materials.

- Coordinate boring works. Necessary for processing deep holes with high accuracy.

- Grinding works. Provide high quality of part surfaces, removing irregularities and defects.

- Locksmith work. Includes a wide range of manual services for assembling, finishing and repairing parts.

Choosing «Promservice» you get not only high-quality products, but also a full range of services from the manufacturer. Our specialists are always ready to consult you and help you choose the best solutions taking into account your individual needs and specifics of your activity.

Services

Promservice provides metalworking and parts manufacturing services using cutting-edge equipment and the latest technologies to ensure high precision in order fulfillment.

CNC turning

CNC milling

Wire EDM

Electrode EDM

Superdrill EDM

Turning

Milling

Coordinate milling

Grinding

Polishing

Fitting

Heat treatment

The Quality of Our Work is Certified by ISO 9001:2015

The quality of our work is certified by the certificate ISO 9001:2015 in the areas of mold and die manufacturing, as well as in the mechanical processing of metals and non-metals. This certification confirms that Promservice has implemented and effectively operates a quality management system aimed at continuous process improvement and full compliance with customer requirements.

Strict control at all stages of production

An important role in the entire production system is played by our quality control department, through which all manufactured parts pass. The specialists of the quality control department (QCD) carry out strict control at all stages of production, from the acceptance of materials and components to the release of finished products. At the control stages of processing, QCD carries out measurements of parts, both manual and with the help of specialized equipment. The quality control department has a high-precision coordinate measuring machine from the German manufacturer MORA Metrology GmbH - Mora Primus. This equipment allows for control measurements of parts with an accuracy of 1.3 microns.

Equipment

High-tech equipment from leading world brands is used in production. The equipment park provides us with accuracy, efficiency and reliability at every stage of the production process.

Advantages of metalworking at Promservice

High quality

All work is performed on modern equipment using modern technologies and proven materials. Each part undergoes quality control. Compliance with the drawing is confirmed by the protocol of the measuring machine.

Wide range of services

You can order parts of any complexity from us, and we will take care of all the worries about their manufacture.

Flexible production program

We carry out both large batches and single orders. We are ready to offer the best solution for each customer.

Working with different types of materials

We work with different types of materials: alloyed and unalloyed steels, graphite, textolite, etc.

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)