Quality control is one of the key aspects of successful production in any industry, especially in metalworking, tooling, and plastic molding. Well-organized quality control helps minimize costs, reduce defects, and increase customer satisfaction. In this article, we will explore why your company needs to implement a quality control system and how to do it effectively.

Why is quality control necessary?

- Reducing defects and costs

Quality control allows you to identify defects at early production stages, minimizing the costs of fixing errors. This is particularly important in the production of complex tooling or parts, where even small mistakes can lead to significant consequences.

- Enhancing company reputation

High-quality products build customer trust and improve your company’s market image.

- Compliance with standards and requirements

Manufacturing that meets international standards, such as ISO, opens access to new markets and increases competitiveness.

- Boosting productivity

Continuous process analysis and improvement optimize production lines and enhance work efficiency.

Key steps to implementing quality control

- Define goals and objectives

Start by analyzing current processes and identifying key metrics you want to improve. For example:

Reducing the defect rate.

Decreasing the time required to fix issues.

- Develop a system of standards

Implement quality standards based on international requirements (e.g., ISO 9001). This helps structure processes and set clear evaluation criteria.

- Train personnel

All employees, from production workers to managers, should understand the importance of quality control. Organize training sessions and workshops to familiarize staff with new standards.

- Use modern technologies

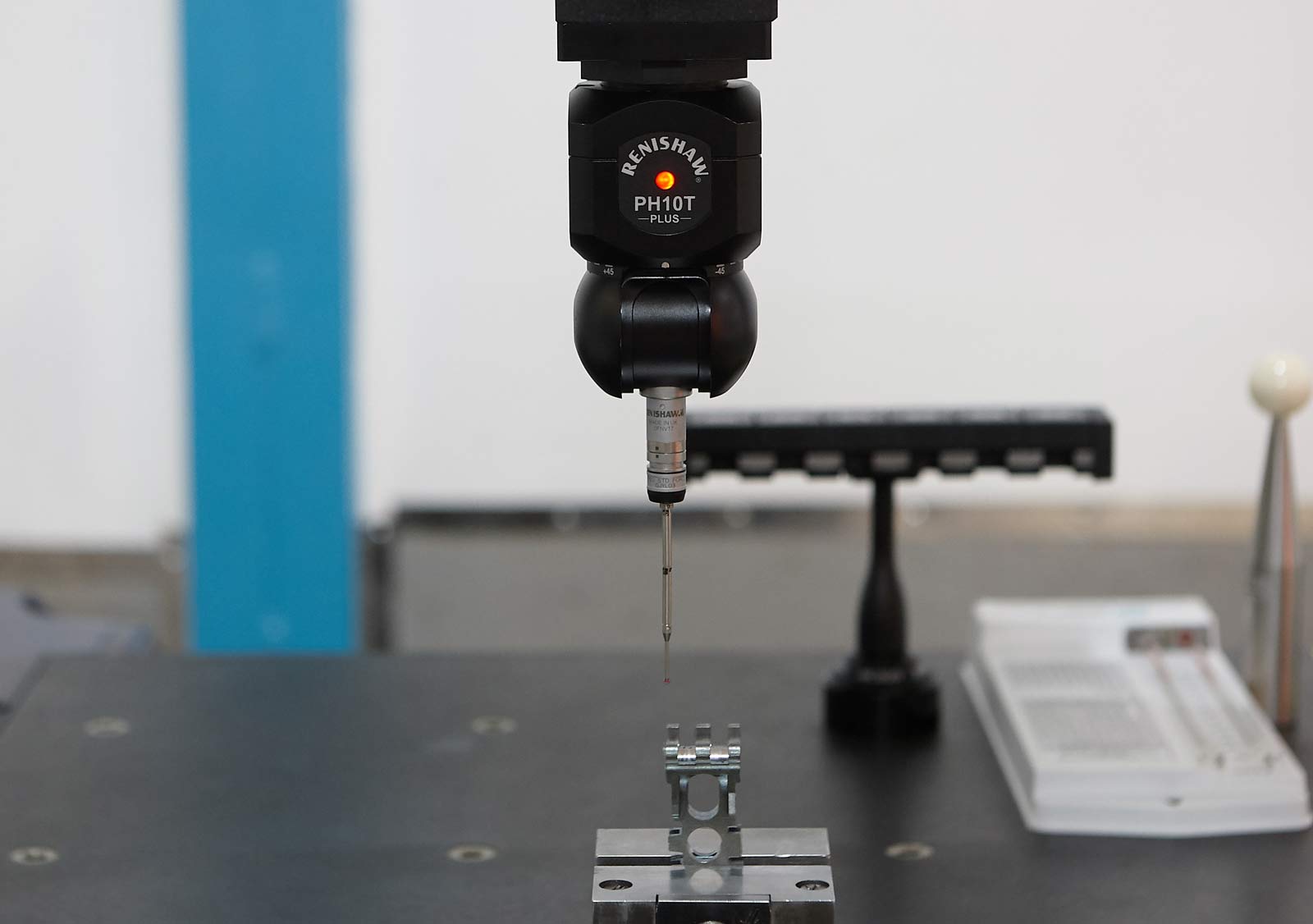

Automated quality control systems, such as visual inspection systems or sensors on production lines, allow for quick detection of inconsistencies.

- Establish a quality control department

Assign specialists to oversee product inspections at every production stage. Their responsibilities include:

- Monitoring raw materials and components.

- Inspecting intermediate production stages.

- Conducting final checks on finished products.

- Analyze and optimize processes

Regularly review quality data to identify weaknesses and make process improvements.

Example of quality control implementation in metalworking

Suppose your company manufactures stainless steel parts. During quality control implementation, you can:

- Test the chemical composition of raw materials before processing.

- Use ultrasonic diagnostics to detect hidden defects.

- Apply automated measurement systems to verify compliance with drawings.

Conclusion

Implementing quality control is an investment in your company’s future. It not only reduces costs and increases profitability but also ensures steady growth and market competitiveness. If your company is ready to take a step toward quality, start with developing a clear strategy and involving specialists to help implement an effective quality control system.