When ordering an injection mold, customers often focus on cavity count, steel, and part quality. But in serial production, the runner system can have an equally strong impact on the economics of the project. The choice between a cold runner and a hot runner affects:

- material consumption and scrap;

- cycle time and productivity;

- part appearance (gate marks) and repeatability;

- tooling price and maintenance requirements.

Promservice designs and manufactures injection molds in Ukraine, including both hot runner and cold runner systems. We help customers select the option that matches their production volume, material, and quality requirements — and we can also support the mold throughout its lifecycle with maintenance, repair, and modernization.

Cold runner system: simple and flexible

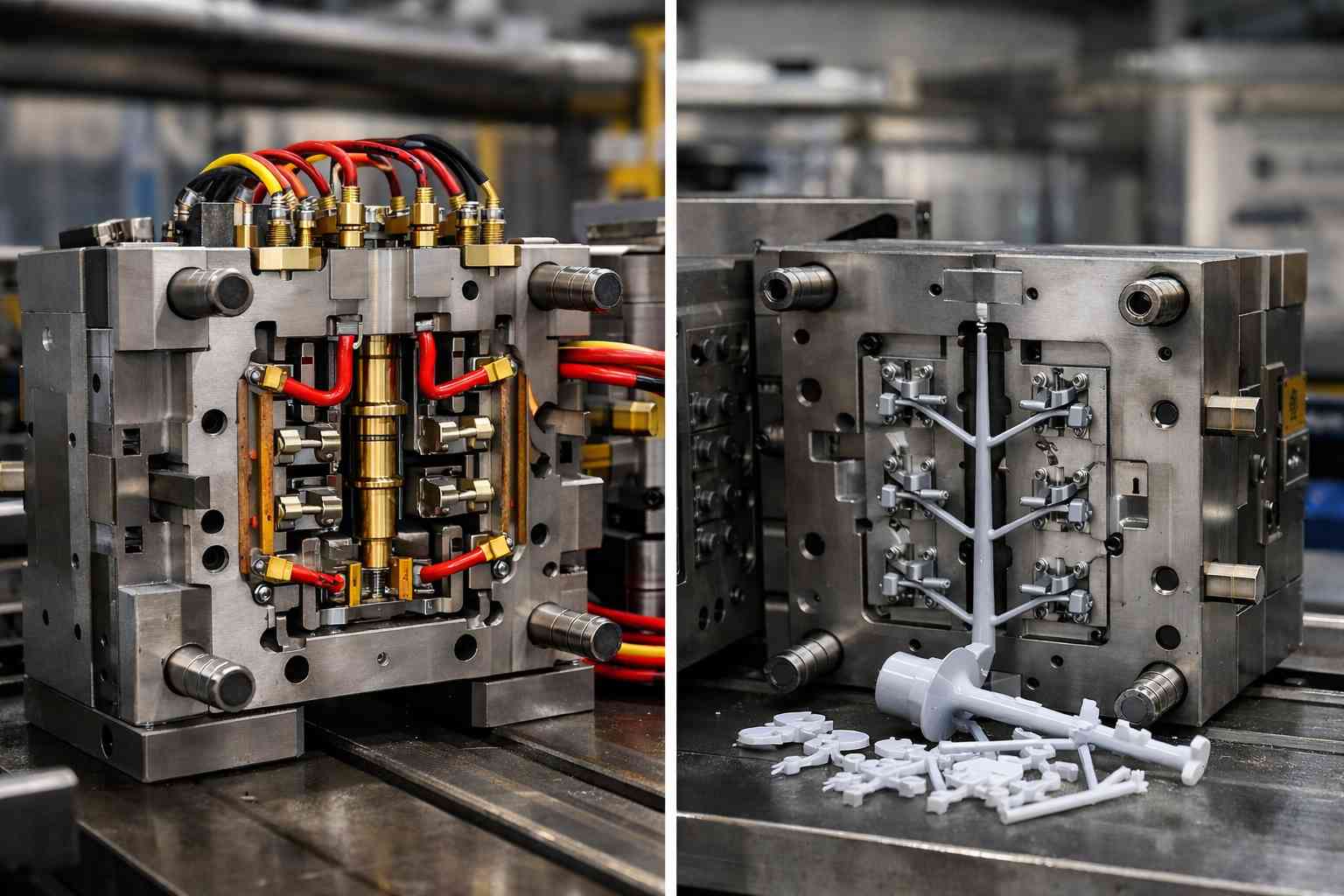

A cold runner mold delivers molten polymer from the machine nozzle through a sprue and runner channels that are part of the mold plates. After each shot, the runner solidifies together with the part and is removed.

Cold runner is often chosen because it offers:

- lower initial mold cost (simpler design and fewer components);

- easier setup and maintenance for many projects;

- fast material or color changeovers (important for short runs);

- good suitability for prototypes and small-to-medium series.

However, the runner becomes regrind or waste. In some industries you can reuse the runner, but in others (cosmetic parts, certain technical requirements, certified products) regrind may be limited or forbidden.

Hot runner system: less waste and higher productivity

A hot runner mold includes a heated manifold and nozzles that keep the polymer in the runner path molten. The part is filled through heated nozzles directly into the cavities, so there is no solid runner removed from each cycle.

Hot runner is typically selected for:

- material savings (especially when the runner weight is significant);

- shorter cycle time (no need to cool a runner and less handling);

- better automation (less manual trimming/degating);

- stable, repeatable molding in high-volume production.

At the same time, hot runners are more complex. They require proper temperature control, correct startup/shutdown procedures, and planned maintenance — otherwise issues like drool, stringing, overheating, or leakage can occur.

Quick comparison: what really changes

Cold runner usually wins on simplicity. Hot runner usually wins on long-term efficiency.

Key practical differences:

- Tooling investment: cold runner is cheaper; hot runner is more expensive upfront.

- Scrap and recycling: cold runner creates runner scrap; hot runner minimizes scrap.

- Cycle time: cold runner often needs additional cooling time; hot runner can be faster.

- Changeovers: cold runner is easier for frequent material/color changes; hot runner needs more careful purging.

- Part appearance: hot runner often allows better gate aesthetics (depends on gate type and part design).

- Maintenance: hot runner needs more attention (heaters, thermocouples, sealing, wiring).

When a cold runner mold is the best choice

Cold runner is usually optimal when:

- the production volume is small or medium;

- you have frequent color/material changes;

- the polymer is inexpensive and runner reuse is allowed;

- you need the most cost-effective tooling for a new project;

- the part geometry allows easy runner separation and trimming;

- you want a robust, easy-to-run solution for different shifts.

In practice, cold runner molds are often the right decision for contract manufacturing with mixed orders, pilot batches, and products that frequently change.

When a hot runner mold pays off

Hot runner typically becomes economically justified when:

- the project is high-volume (continuous or long series);

- the polymer is expensive (engineering plastics, special compounds);

- the runner-to-part weight ratio is high (runner is “too heavy”);

- cycle time is critical and the press is a bottleneck;

- automation is planned and you want less manual finishing;

- gate cosmetics and repeatability are strict requirements.

In mass production, even small savings per cycle can translate into significant annual savings — which is why hot runner solutions are common in large series.

How to estimate ROI: a practical approach

The payback is not a single “magic number.” It is a simple comparison of extra tooling cost vs. savings during production.

Step 1 — Estimate additional tooling cost Hot runner molds cost more due to the manifold, heated nozzles, temperature control components, and higher assembly complexity.

Step 2 — Calculate material savings Estimate runner weight in a cold runner mold (g) and multiply by material cost (€/kg or $/kg). Then multiply by the number of parts per year. If regrind is allowed, apply the realistic regrind percentage and quality limitations.

Step 3 — Calculate cycle time savings Even a 1–2 second reduction in cycle time can increase output per shift. Convert saved seconds into additional parts per hour and evaluate the value of extra capacity on your press.

Step 4 — Add secondary savings Hot runner can reduce labor for trimming and handling, reduce packaging volume (no runners), and improve process stability — often lowering scrap rates.

A simple ROI formula:

- Payback period = (extra hot runner cost) / (annual savings)

Promservice can help you estimate these inputs during the engineering stage, based on part geometry, material, cavity layout, and expected production volumes.

Common mistakes when choosing a runner system

To avoid costly rework, watch out for these typical issues:

- choosing hot runner for a project with frequent color changes and short runs;

- underestimating the runner weight and scrap cost in a cold runner mold;

- ignoring gate location requirements (appearance, weld lines, strength zones);

- not planning cooling correctly (cycle time losses and warpage);

- skipping maintenance planning for hot runner components.

The best choice is always the one that fits your production reality — not just the “more expensive” or “more modern” option.

Promservice approach: engineering-first selection

We treat runner system selection as part of the full mold engineering task. Depending on your project goals, we can:

- analyze drawings and the production plan (batch size, shifts, automation);

- propose a cold runner or hot runner concept with cavity layout and gating;

- design a mold with reliable cooling, venting, and maintainability;

- manufacture the mold and conduct trial runs, tuning the process if needed;

- provide service: maintenance, repair, refurbishment, and modernization.

If you already have an operating mold, we can also assess whether modernization (for example, optimizing gating or adding replaceable inserts in wear zones) is technically and economically reasonable.

Need a hot runner or cold runner mold in Ukraine?

Promservice designs and manufactures injection molds with cold runner or hot runner systems, and supports customers with injection molding and tooling service. Contact us — we will review your part, calculate the best-fit option, and help you reach stable production with a clear economic justification.