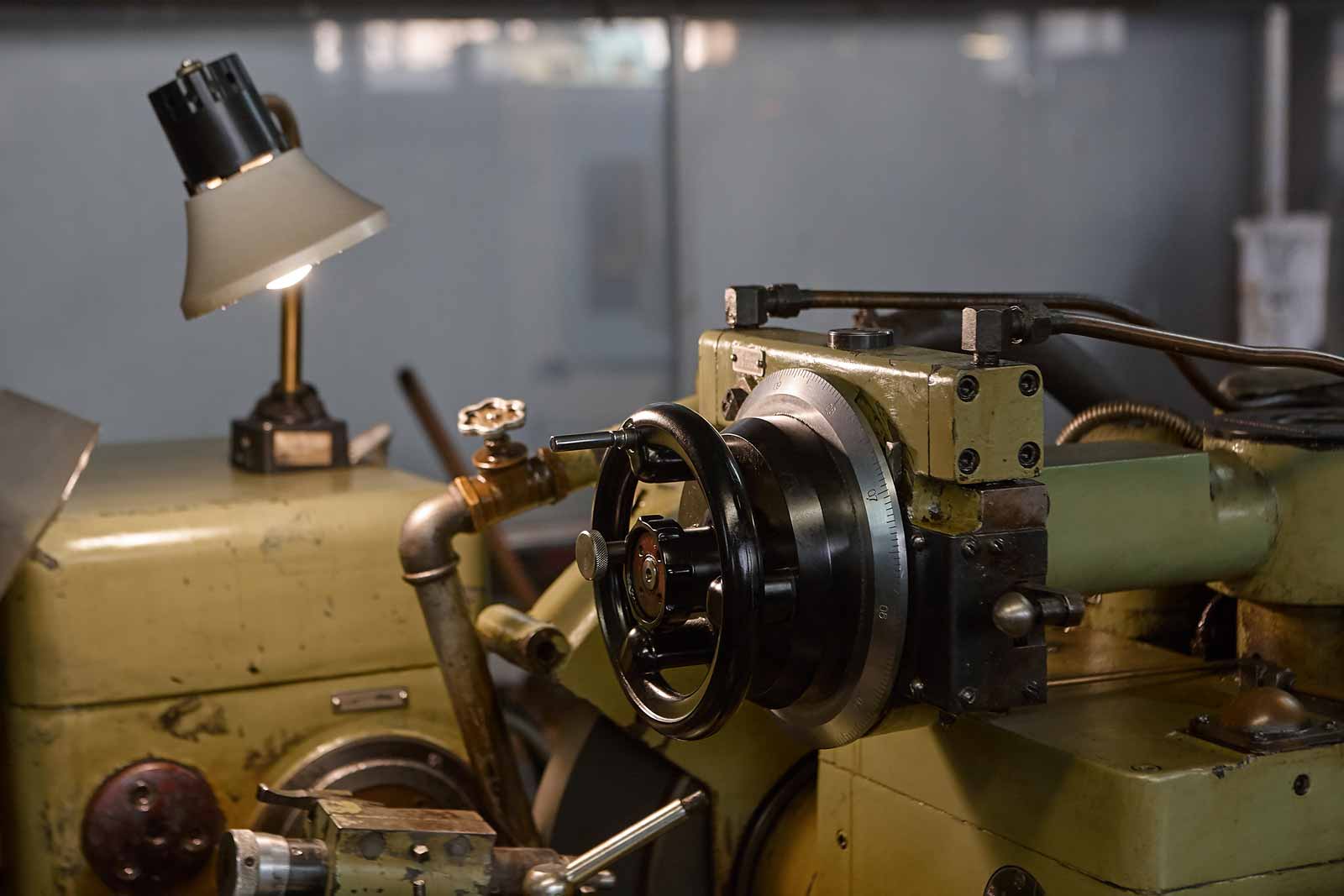

Metalworking lathes are designed for threading and machining various types of parts. These machines are in demand by both large industrial enterprises and individual customers who want to equip their home workshops with reliable and high-quality equipment.

The modern market offers both traditional lathes and lathes with Computer Numerical Control (CNC). You can choose models with stepless speed control and tubular lathes with CNC. In addition, a wide range of spare parts and additional equipment is available for these machines.

Characteristics of metalworking lathes

Modern metalworking lathes are characterized by:

- functionality;

- reliability;

- operational safety;

- durability and high-quality finish.

These machines comply with international safety standards and are designed with modern efficiency and ergonomics requirements in mind. Only standardized components from reputable manufacturers are used in their production.

Traditional lathes are valued for their robust construction and reliable operation over many years of use. They provide high precision in machining metal parts. On the other hand, CNC lathes allow for the processing of virtually any material in a short time.

Automation of the machining process enhances productivity and workplace safety. CNC lathes are ideal for processing complex surfaces where high precision is required. They are widely used in mass production, especially in the automotive industry. Tubular lathes, thanks to their stable cast iron base, effectively dampen vibrations, ensuring high precision even when machining large and heavy parts.

How to choose the right lathe

The phrase "You get what you pay for" aptly describes the purchase of heavy industrial equipment, including lathes. When buying a home metal lathe, it's important to understand that its capabilities will be limited compared to industrial models.

If you need an affordable benchtop metal lathe, choose from optimal models that are suitable for basic and intermediate tasks. These lathes handle small workpieces and low volumes of work excellently. For private use, their capabilities are generally sufficient.

However, for maximum functionality and working with especially hard metals, you will need more powerful equipment. Heavy stationary lathes have several advantages over benchtop models: they allow for deeper cuts, offer greater rigidity, and have reduced vibration.

Stationary lathes are characterized by a longer service life and higher precision, which is especially important when performing precision work in large volumes. It is recommended to choose lathes with a heavy cast iron base, as they provide better stability and accuracy compared to models made of welded steel.

Conclusion

The correct choice of a metalworking lathe plays a crucial role in ensuring efficiency and quality in machining. When purchasing a lathe, it is important to consider the tasks you intend to perform, as well as the requirements for precision and durability of the equipment. Depending on the scale and specifics of your production, the choice may range from compact benchtop models for home use to heavy industrial machines capable of handling large volumes of work and processing complex materials. Investing in quality equipment will allow you to significantly increase productivity, improve product quality, and strengthen your market position.