Molds are the foundation of high-precision mass production. They enable the creation of products from plastics, metals, silicones, and other materials with minimal deviations and high repeatability. This is especially important in industries such as automotive manufacturing, instrumentation, electronics, and medicine.

What is a mold?

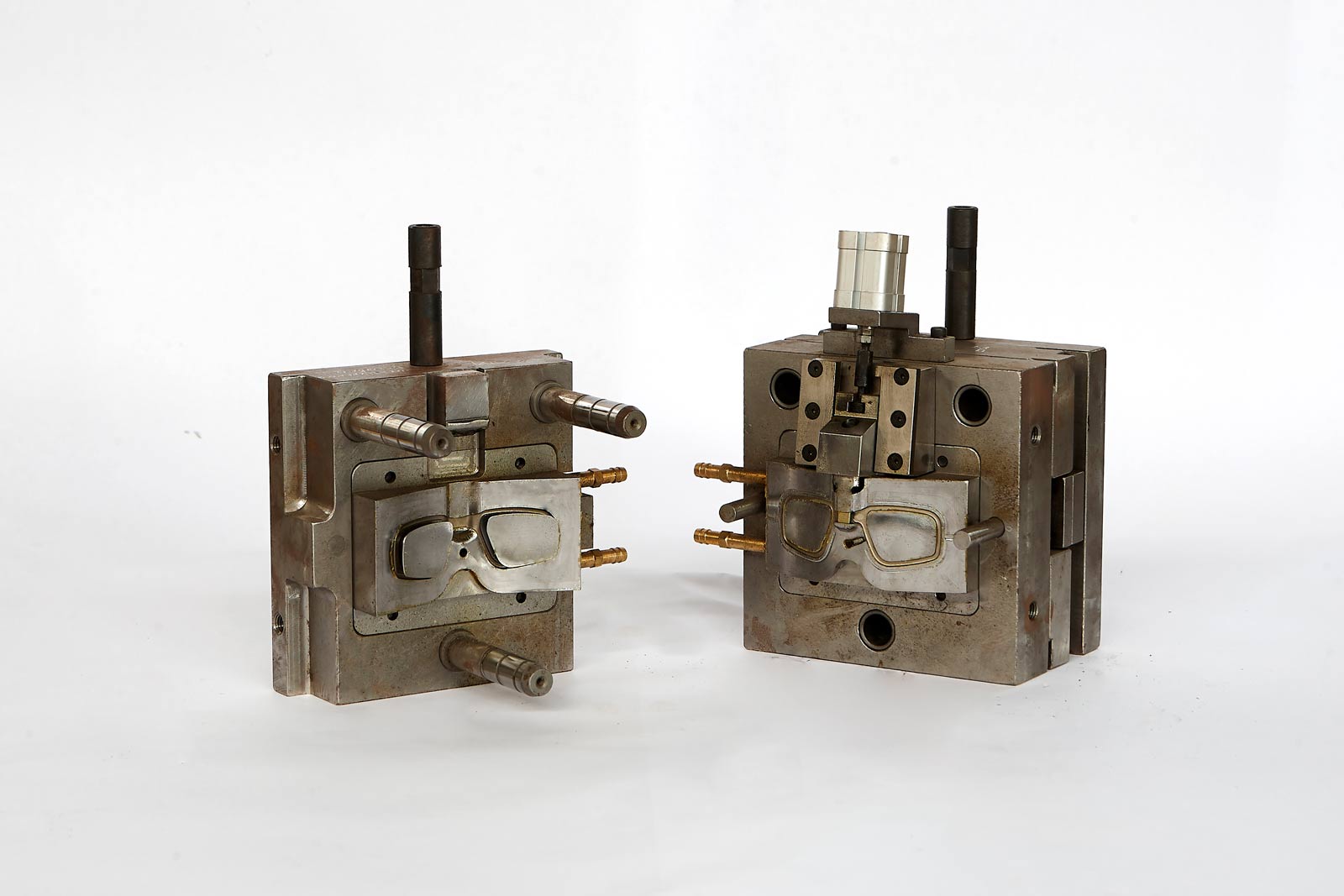

A mold is a complex technical tool designed for manufacturing products through pressure forming. It consists of two main parts — the cavity and the core — which together form the mold cavity. During the production cycle, molten material is injected into this cavity, where it takes the required shape and solidifies.

What types of molds do we manufacture?

Our company designs and manufactures molds tailored to the individual needs of our clients. We produce:

- molds with automatic or manual part ejection;

- cold runner and hot runner systems;

- single- and multi-cavity molds;

- molds with interchangeable inserts (logos, cavities, cores) for producing different parts using the same tooling.

We use modern equipment that allows us to achieve precision and stability, even with the most complex projects.

Applications of molds

The molds we manufacture are used in the following technologies:

- plastic injection molding;

- aluminum and zinc alloy casting;

- silicone and rubber compression molding;

- direct compression of thermosetting polymers;

- MIM technology (Metal Injection Molding) — the formation of metal parts from powder with high precision and minimal post-processing.

Thanks to our wide range of solutions, our products are used in various industrial sectors — from mass production of consumer goods to high-precision components for engineering systems.

Why choose us?

We offer a full range of services: from design and 3D modeling to launching serial production. Key advantages:

- individual approach to each project;

- highly qualified engineering staff;

- modern, high-precision equipment;

- certified quality management system (ISO 9001:2015);

- warranty and post-warranty service.

Control at every stage of production ensures on-time delivery and consistently high product quality.

If you're looking for a reliable partner in the design and manufacturing of molds — we are ready to offer the best solutions for your needs.