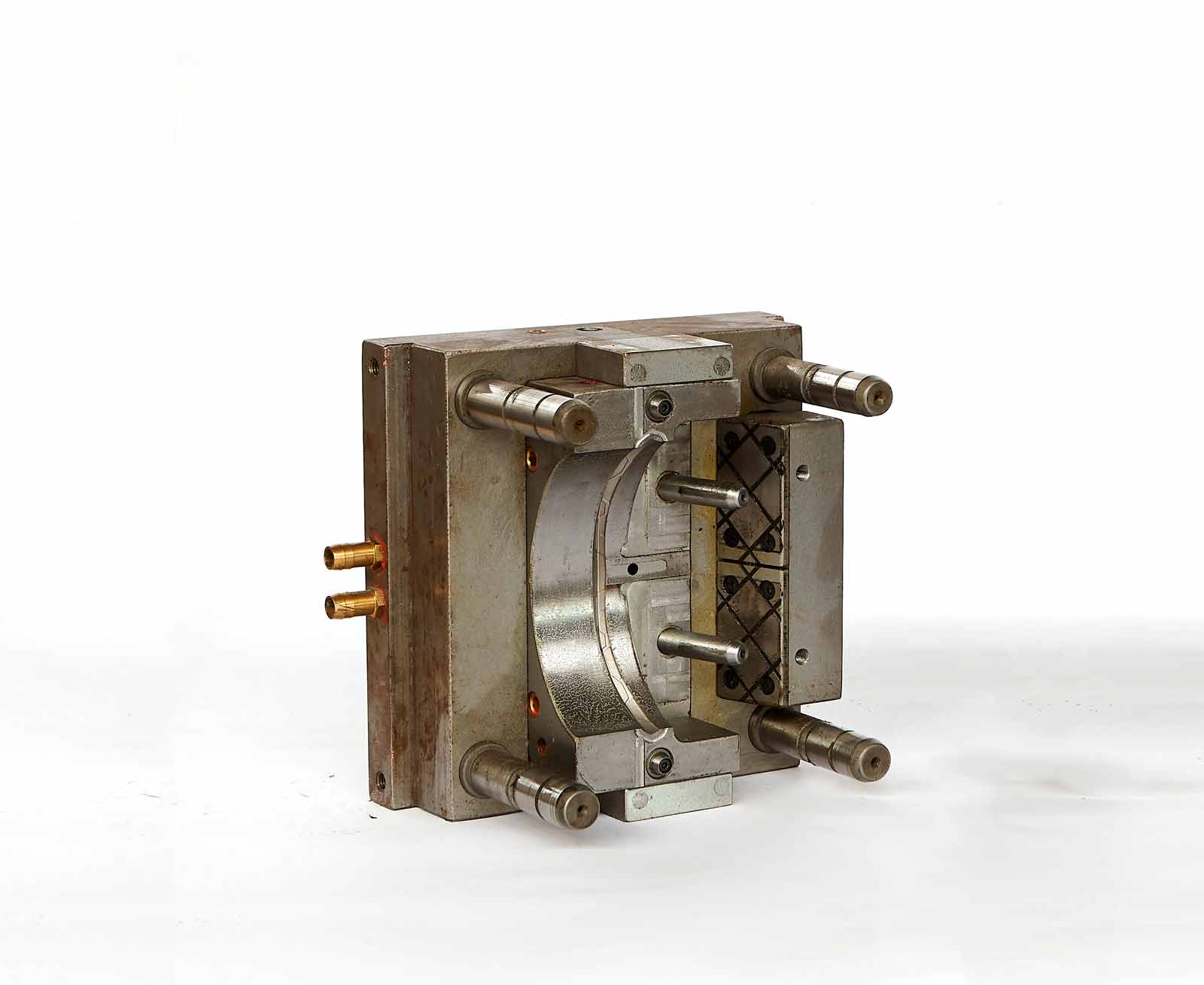

Mold manufacturing is not just mechanical metalworking — it is a complex engineering process involving expertise in materials science, mechanics, thermodynamics, and automation. A mold must not only ensure geometric precision of the product but also withstand hundreds of thousands or even millions of working cycles without quality degradation.

Where Does Mold Production Begin?

Everything starts with a technical brief. The client provides drawings or a 3D model of the future product, along with information about the material, operating conditions, and the expected production volume.

Before designing the mold, we create an injection-optimized model of the part — considering draft angles, parting lines, possible shrinkage, and other details. This model is approved by the client and becomes the basis for mold development.

At this stage, it is important to define:

- the type of molding (plastic, metal, silicone, etc.);

- the number of cavities;

- the cooling system;

- the parting line and ejection method.

Our process engineers develop the mold structure and perform strength, thermal expansion, flow, and cooling channel calculations. We use CAD/CAM/CAE software to simulate the mold’s behavior during injection.

Manufacturing and Assembly

After project approval, the machining phase begins. Tool steel blanks are processed through milling, EDM, grinding, and hardening. High-precision assembly requires tolerances within hundredths of a millimeter — especially in parting lines and moving components.

We may incorporate:

- hot runner systems (to reduce material waste);

- interchangeable inserts (to adapt molds for different parts);

- gas and hydraulic ejectors.

Testing and Tuning

The finished mold undergoes trial injection. At this stage, potential defects such as short shots, shrinkage, or deformation are identified. Based on test results, adjustments are made to optimize cooling and injection pressure. Once fine-tuned, the mold is handed over to the client or kept in-house for serial production.

Maintenance and Service Life

A mold is a long-term investment. To ensure longevity, regular maintenance is essential:

- cleaning of cooling channels;

- inspection of locks and guides;

- lubrication of moving parts;

- wear and crack checks.

Depending on the material and design, mold service life can range from 100,000 to 2,000,000 cycles. We also offer mold repair, refurbishment, and modernization services.

Why It Matters

A well-designed and properly maintained mold:

- shortens cycle times;

- reduces defects;

- ensures consistent product quality;

- accelerates return on investment.